When working with ERP systems or listing products on e-commerce platforms, you're often required to assign a unique identifier to each item, which can come in the form of an "item number." "material code," or "product ID," among others. This process is known as product or item coding.

Take ballpoint pen refills as an example. Refills from different brands can vary in compatible pen models, colors, and tip sizes. If we labeled them all simply as "ballpoint pen refills," we wouldn't be able to tell them apart. That's why each one needs its own "identity card" or item number to clearly distinguish them. By assigning a unique code to each item, systems and employees can clearly identify and differentiate similar products.

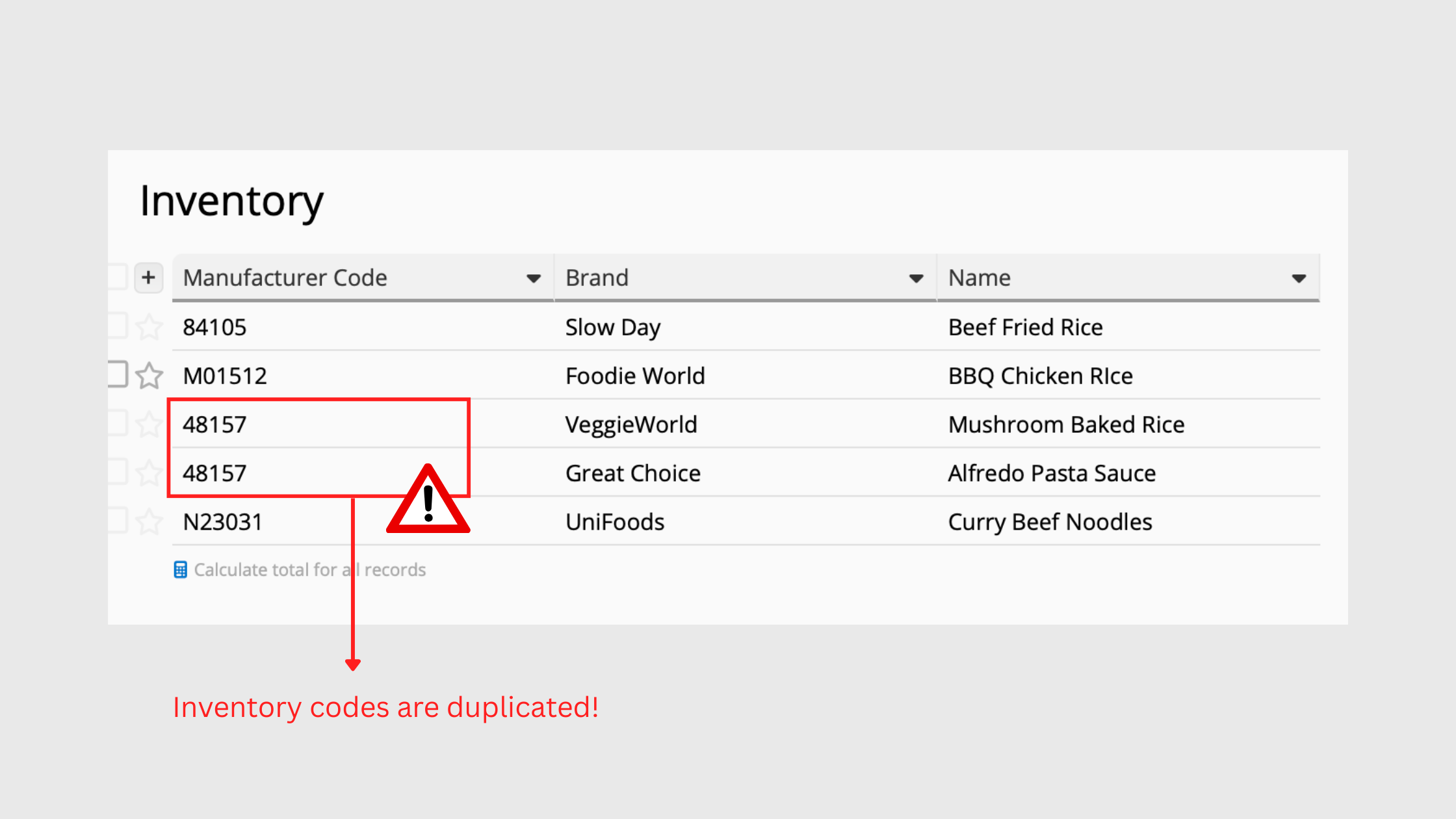

To achieve clear item identification, having a company-wide coding standard is important. Avoid directly using external codes, such as vendor item numbers, as different vendors may coincidentally use the same codes, resulting in duplicates within your system.

Another common issue is the absence of a universally applied, unique coding system. In companies with multiple departments, each team may develop their own internal coding system to optimize efficiency, but this can result in the same code being used for different items across departments— which can be chaotic.

To maintain uniqueness, it is best to re-code all external materials and products internally. Coding rules should be standardized across all departments, coordinated collaboratively, and strictly enforced. To further prevent conflicts, you can leverage the "non-duplicate" or "unique" setting in your information system, or use Excel's data validation feature to ensure duplicate codes cannot be entered.

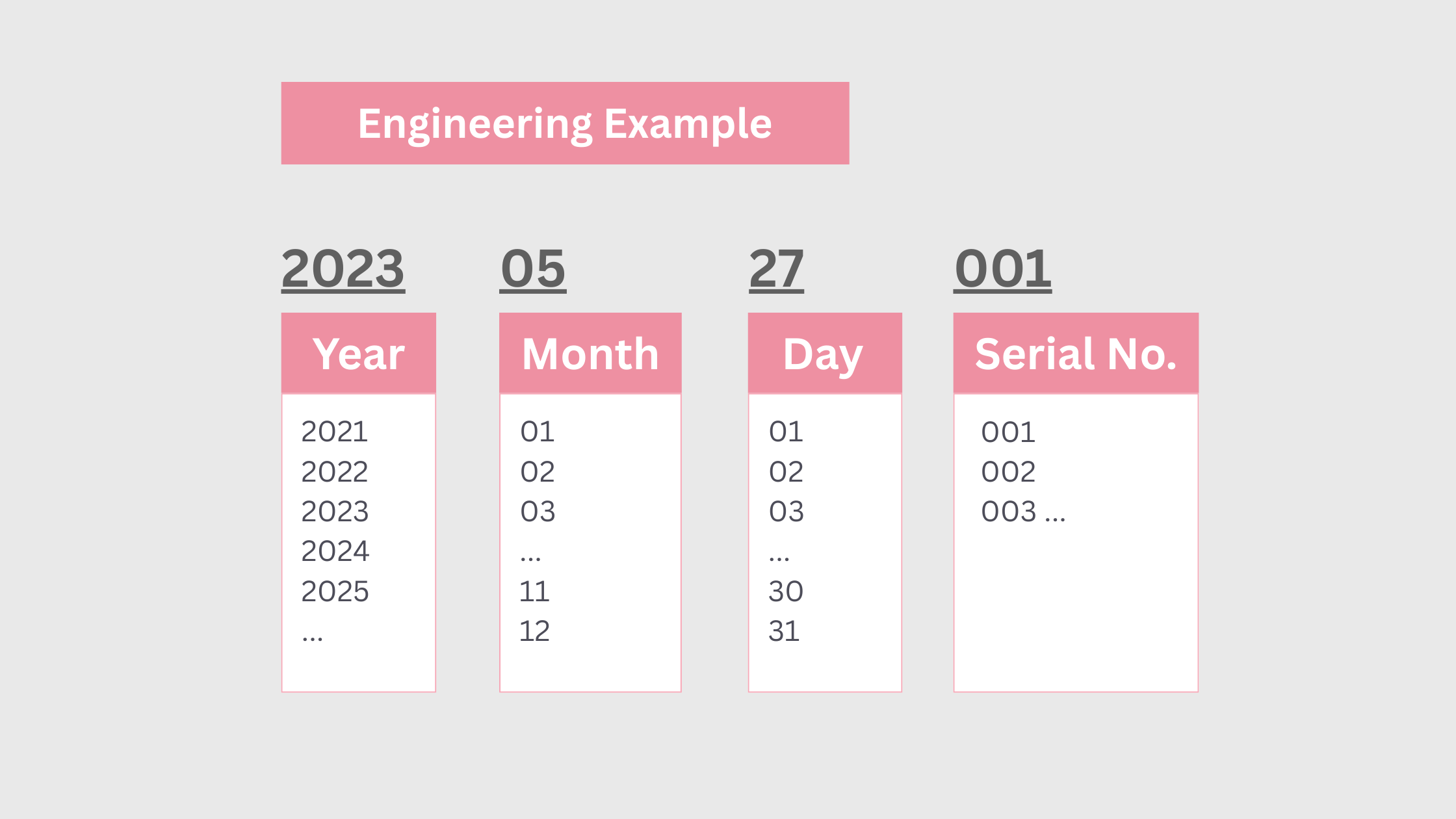

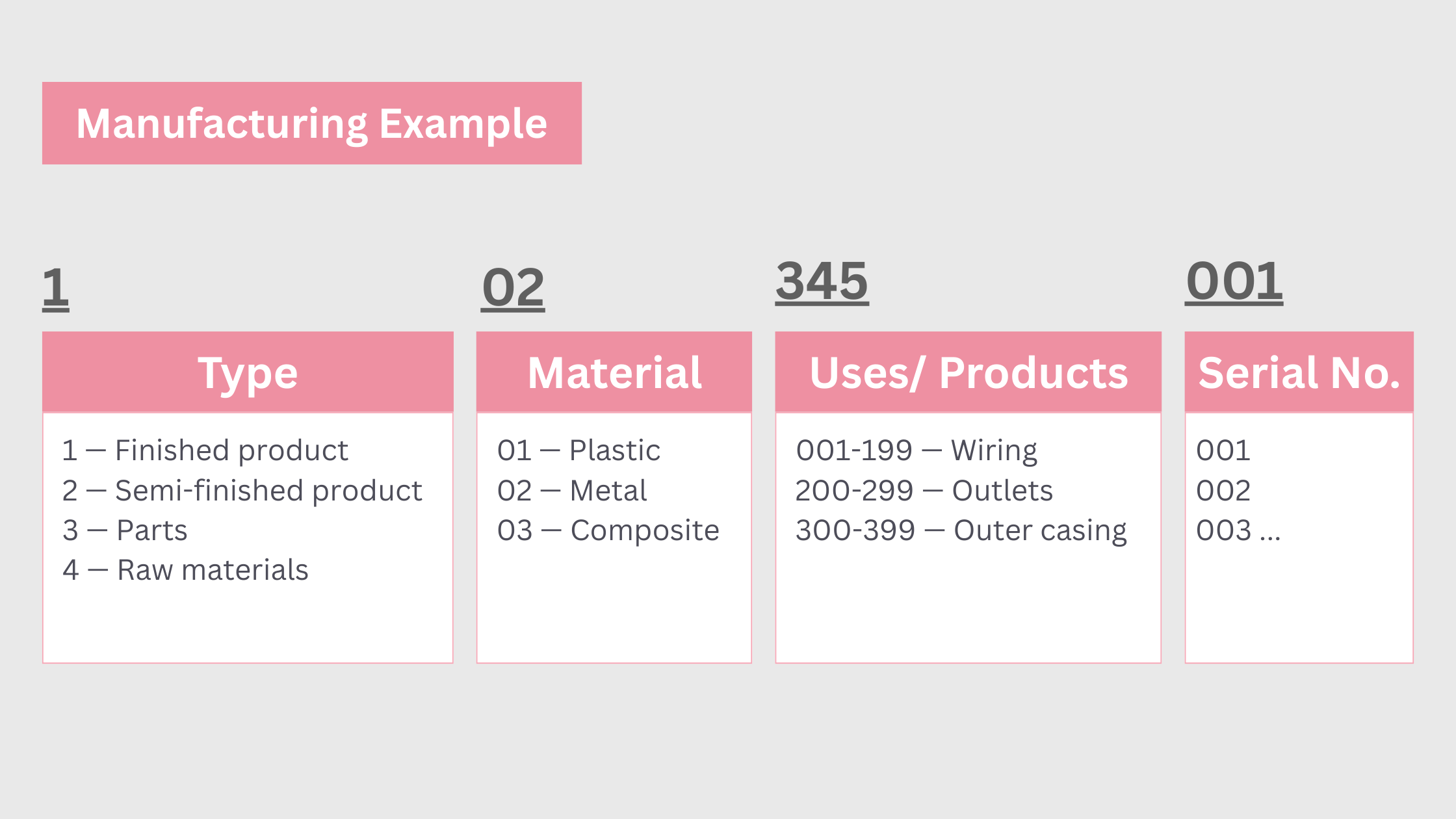

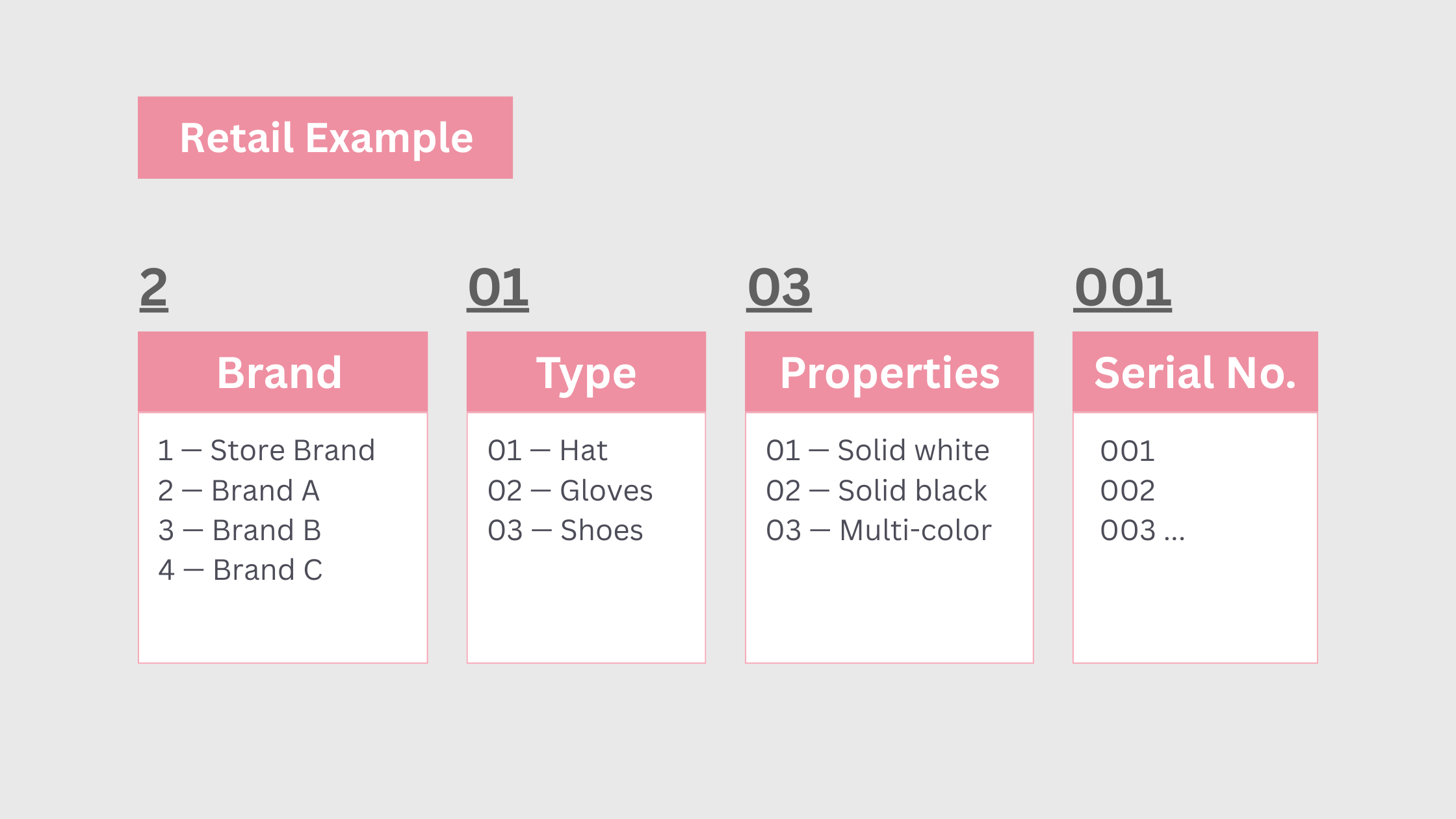

If you're not sure where to start, you can refer to our sample coding structures for manufacturing, retail, and engineering projects.

Since manufacturing often involves large volumes of data, it is best to begin by categorizing the items by type. Then start with a top-level category like "materials," then break it down further by physical properties or usage. This approach makes it easier to filter and locate the items you need.

In retail, it is helpful to be able to filter product codes using product categories. For example, start with the brand, then narrow it down by type and attributes such as material or color to quickly find the products you need.

In engineering, coding can be kept simple by classifying items directly by completion date. This provides a quick and efficient way to filter and retrieve the information you need.